Chemical and Acid Resistant Epoxy Novolac Coating Kit - Commando Coat 300X

- Industrial-grade durability

- 2-layer epoxy novolac system

- Temperature-resistant for hot wash-down areas

| Details | Specification |

|---|---|

| Epoxy Primer Type | Two component novolac epoxy primer |

| Topcoat Type | Two component high solids novolac epoxy topcoat |

| Min Optimal Temp | 50 |

| Max Optimal Temp | 90 |

| Substrate/Surface Material | Concrete |

| Indoor/Outdoor | Indoor |

| DIY Friendly | Yes |

| Resists Blistering | Yes |

| Resists Chemicals | Yes |

| Coating Type | Novolac epoxy |

Commando Coat 300X - See TDS

Where can I use the Commando Coat 300X?

This epoxy floor coating is ideal for:

- Chemical factories

- Battery storage rooms

- Breweries, wineries, and distilleries

- Food processing plants

- Chrome plating facilities

- Storage tanks and other industrial settings

Does the Commando Coat 300X resist temperature fluctuations?

Yes! This epoxy can withstand hot wash-down areas and extreme temperatures without compromising durability.

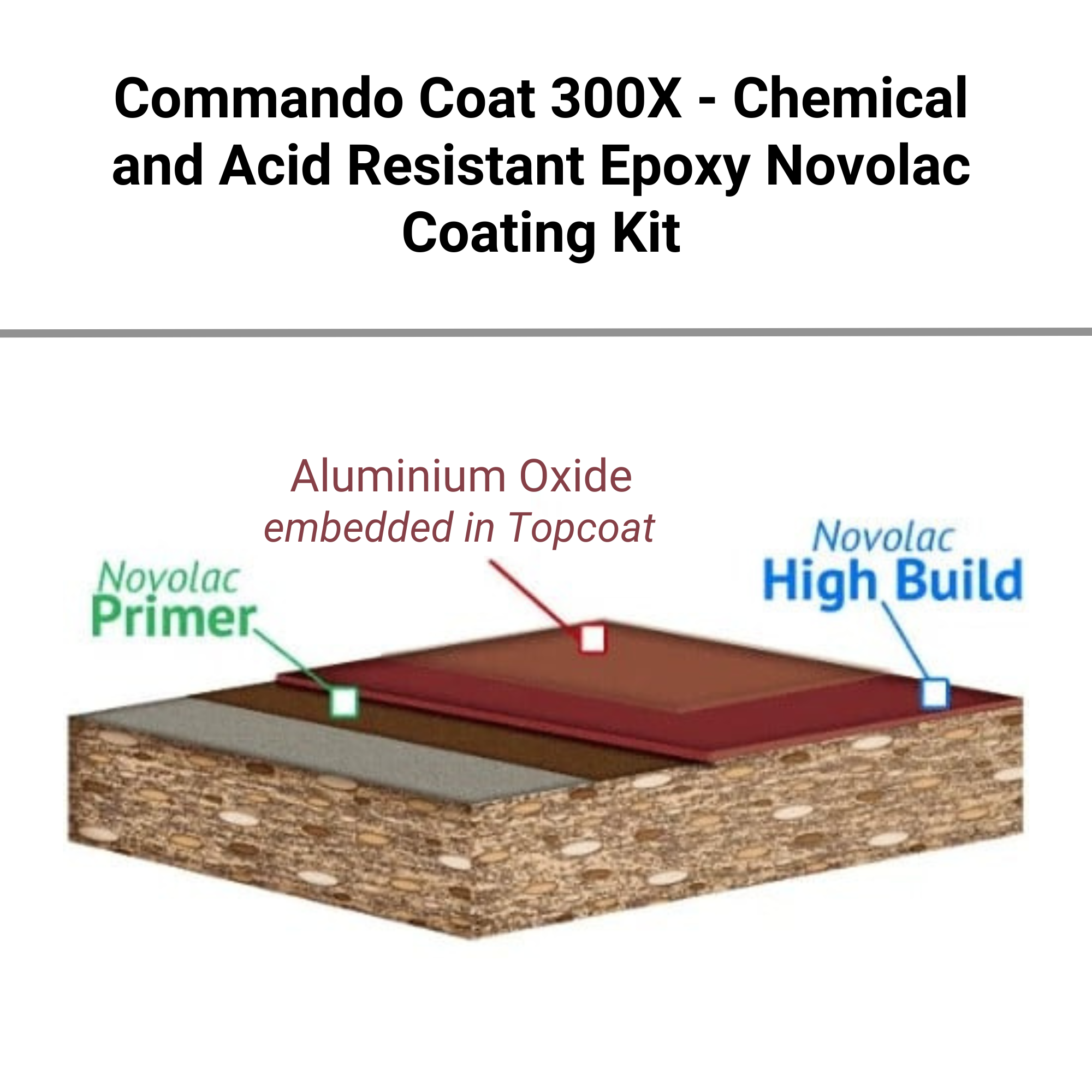

How does the 2-layer system work?

The two-layer application consists of:

- Base/Primer Coat – A self-priming, chemical-resistant epoxy novolac primer that grips onto the concrete.

- Topcoat – A durable, chemical-resistant epoxy novolac topcoat that bonds to the primer, creating a strong, seamless protective surface.

Does this coating provide an anti-slip surface?

Yes, a non-skid additive is included to enhance traction and reduce slip hazards.

Is this epoxy coating UV-resistant?

While the standard formula may be affected by extreme UV exposure, a UV-inhibiting clear version is available upon request. Contact us for details.

The Commando Coat 300X - Chemical and Acid Resistant Epoxy Novolac Coating Kit is a two layer acid and chemical resistant novolac coating system. Simply enter your desired square footage amount and the price will automatically be calculated.

This system features a single layer of enhanced epoxy novolac primer followed by a single layer of novolac topcoat. This 2 layer floor coating system is ideal for use in hostile environments where chemical/acid resistance is of the utmost importance. We suggest using this on chemical factories, breweries, wineries, distilleries, processing plants, battery storage rooms, chrome plating facilities, and other similar applications.

This 2 layer coating is specifically designed for application where splash/spill of acids, chemicals, and solvents occur frequently. The 2 layer build up strengthens your floor by allowing the primer ”grip” to the concrete and then letting the topcoat bond to the primer resulting in a super strong build of highly effective floor coatings. This floor can also withstand normal wear and tear, impact falls, PH cleaners, fluids, any other substance that might get onto your floor. It is super easy to clean, just use a mop or wet vac and have you floor looking like new in no time.

You will receive:

- Base/Primer Coat - Self Priming Chemical Resistant Epoxy Novolac Coating

- Topcoat - Chemical Resistant Epoxy Novolac Topcoat

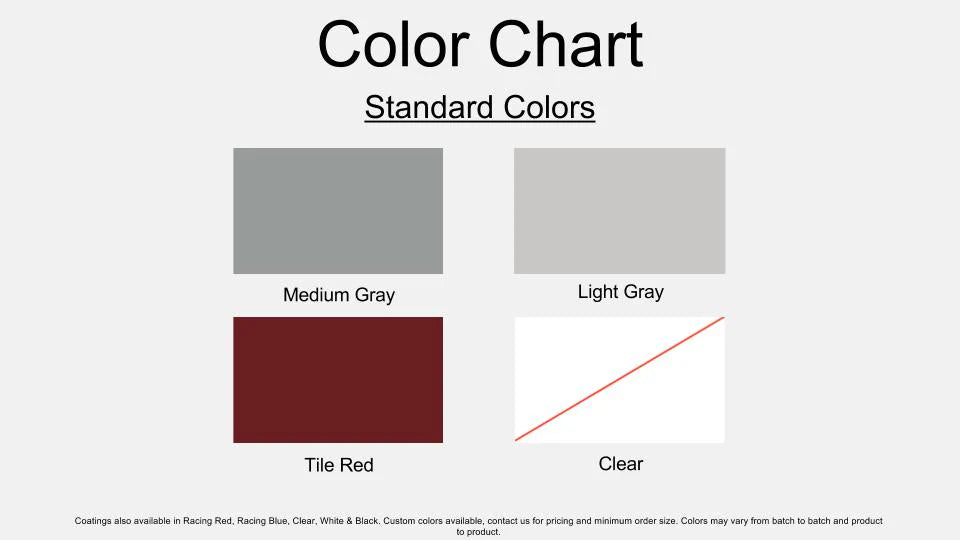

Choose from over 3 colors for you floor! Clear and custom color are available upon request. Bright colors such as red, yellow, white, and other lighter colors require greater pigmentation. Please inquire to find out pricing.

*Colors or gloss may be affected by high/low temperature, extreme lighting exposure. Clear version is available special order with UV inhibitors to prevent yellowing. Please call or email to order.

EACH KIT INCLUDES

- Prep/etch solution for prepping the floor

- Roller pad

- Roller frame

- Mixing stick/Metal Mixer

- Non-skid additive

- Mixing Bucket with liner

- Instructions

- Spike Shoes* (only comes with the purchase of 1000 sq/ft or more)